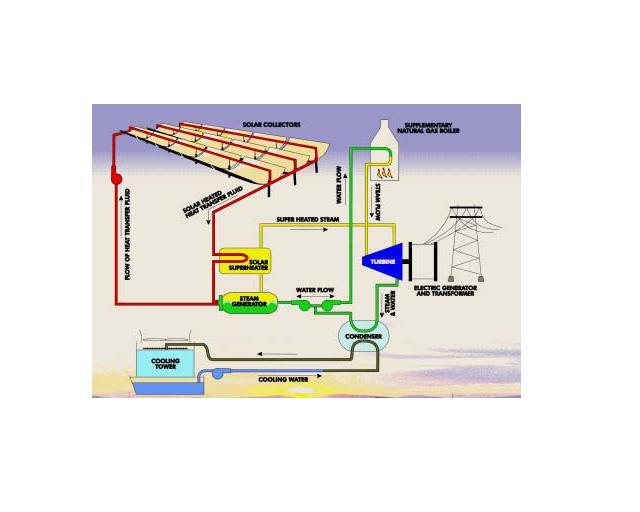

Solar parabolic trough technology has evolved to a point where the efficiency is around 21% in terms of conversion of direct solar radiation into grid electricity. A parabolic trough is one type of solar thermal collector. It is generally constructed as a long parabolic mirror (usually coated silver or polished aluminium) with a receiving tube running its length at the focal point. Sunlight is reflected by the mirror and concentrated on the heating tube. The trough is usually aligned on a north-south axis, and rotated to track the sun. Heat transfer fluid (often oil) runs through the tube to absorb the concentrated sunlight. The heat transfer fluid is then used to heat steam and returns to a series of heat exchangers in the power block where the fluid is used to generate high-pressure superheated steam. The superheated steam is then fed to a conventional reheat steam turbine/generator to produce electricity. The spent steam from the turbine is condensed in a standard condenser and returned to the heat exchangers via condensate and feedwater pumps to be transformed back into steam.

There are a number of solar parabolic trough electricity plants which have been designed to use solar energy as the primary energy source to produce electricity. The plants can operate at full rated power using solar energy alone given sufficient solar input. During the hot summer months, the plants typically operate for 10 to 12 hours a day generating electric output, although plants are often hybrid solar/fossil plants. This means they have a backup fossil-fired capability that can be used to supplement the solar output during periods of low solar radiation.

The success of this technology is primarily indicated by the operation of nine large commercial-scale solar power plants, the first of which has been operating in the California Mojave Desert since 1984.

The Liddell Power Station in Australia has four 500MW coalfired generators. The solar array seen below feeds steam directly into the power station steam cycle producing an extra 5MW of output solely from solar energy. The company, Solar Heat and Power responsible for the project are about to start on a much bigger project in the United States.

Integrated Solar Combined Cycle System (ISCCS)

The ISCCS is a new design concept that integrates a parabolic trough plant with a gas turbine combined-cycle plant. The ISCCS has generated much interest because it offers an innovative way to reduce cost and improve the overall solar-to-electric efficiency.