How does Integrated Gasification Combined Cycle IGCC Work?

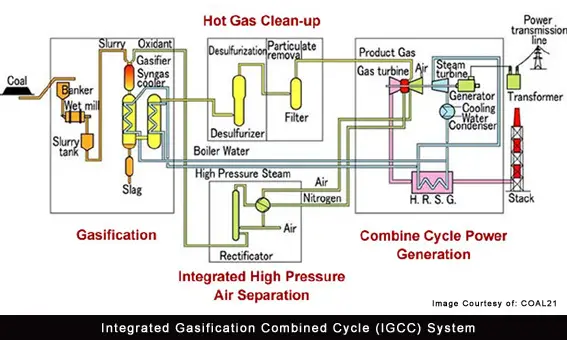

Integrated Gasification Combined Cycle IGCC is a combination of two leading technologies. The first technology is called coal gasification, which uses coal to create a clean-burning gas (syngas). The second technology is called combined-cycle, which is the most efficient method of producing electricity commercially available today.

Coal Gasification: The gasification portion of the IGCC plant produces a clean coal gas (syngas) which fuels the combustion turbine. Coal is combined with oxygen in the gasifier to produce the gaseous fuel, mainly hydrogen and carbon monoxide. The gas is then cleaned by a gas cleanup process. After cleaning, the coal gas is used in the combustion turbine to produce electricity.

Combined-cycle: This design consists of a combustion turbine/generator, a heat recovery steam generator, and a steam turbine/generator. The exhaust heat from the combustion turbine is recovered in the heat recovery steam generator to produce steam. This steam then passes through a steam turbine to power another generator, which produces more electricity. Combined cycle is more efficient than conventional power generating systems because it re-uses waste heat to produce more electricity. The integration of these technologies provides the high efficiency of the combined-cycle design with the low cost of coal for fuel.

Advantages of IGCC

Integrated Gasification Combined Cycle IGCC is an advanced technology that represents the cleanest of currently available coal technologies. Advantages of IGCC over current conventional coal-based power generation systems include: Higher efficiencies and lower emissions:

Improvements in efficiency dramatically reduce emissions from coal combustion as the graph at right highlights. Increasing efficiency from 35 to 40%, for example, reduces carbon dioxide emissions by over 10%.

With efficiencies currently approaching 50%, IGCC power plants use less coal and produce much lower emissions of carbon dioxide than conventional power plants.

With development of new gas turbine concepts and increased process temperatures efficiencies of more than 60% are being targeted.

Higher output: Using syngas in a gas turbine increases its output, especially when nitrogen from an oxygen blown unit is fed to the turbine. Thus a turbine rated at 170MW when fired on natural gas can yield 190MW or more on syngas. Furthermore, output is less dependent on ambient temperature than is the case with natural gas.

Product flexibility – including carbon capture and hydrogen production: The gasification process in IGCC enables the production of not only electricity, but a range of chemicals, by-products for industrial use, and transport fuels (see graphic).

Carbon dioxide can be captured from the coal syngas (carbon monoxide and hydrogen) through a water/gas shift process.

The CO2 can be captured in a concentrated stream, making it easier to convert into other products, or to sequester (for example, store underground) – see CO2 Capture and Storage.

An added advantage in this process is that there are low additional costs for carbon capture, particularly if the plant is oxygen driven.

In addition to electricity generation, hydrogen produced from the process can potentially be used as a transport fuel, in fuel cells.

(information sourced from: ‘Coal21’)