Sliver solar cells address the major issue relating to the uptake of solar electric systems – the cost. Sliver® cells use up to 90% less silicon compared with mono crystalline cells of equivalent output resulting in lower module costs.

Sliver solar cells use as little as one tenth the amount of hyper-pure silicon as in square solar PV technology, giving them the potential to produce electricity at grid-competitive prices (once grid prices grow much more expensive). However, the process, while using less silicon, is itself a little expensive. Costs may well fall as larger scale production begins and the technology becomes commonplace.

Sliver solar cells were invented at the Australian National University with funding assistance from the Australian Government and Origin Energy.

Fabrication

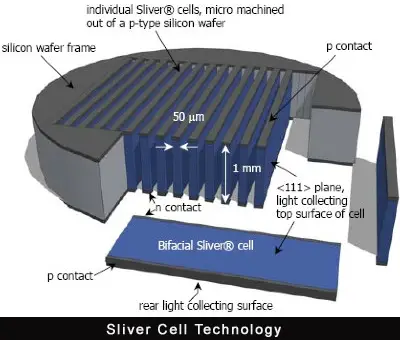

“Sliver® solar cells are fabricated using 1 – 2 mm thick silicon wafers. The key step in Sliver® cell processing is to form deep narrow grooves all the way through the wafer. Several processes can be used including laser scribing, a dicing saw or an anisotropic etching process.

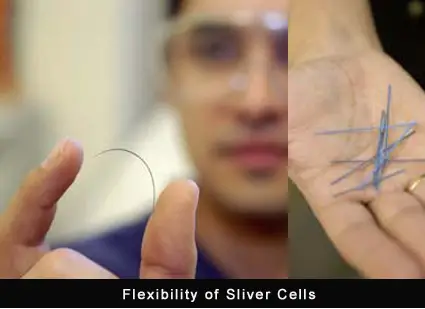

The result is a wafer cut into a series of slivers, with each sliver approximately 50-100mm long, 1-2mm wide and 40-60ìm thick. Note that after creating the grooves the slivers are still attached to the wafer. This allows the slivers to undergo further steps in the fabrication process before they are removed and assembled into modules.

Cells can be laid out with no gap between or with any spacing between slivers up to about 1.5 times the width of each cell. With a scattering reflector attached to the rear of each module, most of the light incident in the space between the cells can still be captured. Sliver® cells are truly bifacial as they respond equally well to light on either surface.

This means less silicon per unit area, greater area covered per unit mass of silicon, lower $/W, lower overall system costs or greater efficiency if more expensive materials and processes are used. These are all different ways of saying that Sliver® cells use approximately one tenth the amount of expensive silicon compared with conventional cells.

A wafer (assume 150mm diameter) configured as a conventional solar cell has an area of 177cm2. However, the same wafer, when processed to produce Sliver® cells, can be used to cover up to 5,000 cm2 of module area, which is 30 times better than for conventional technology.

More information is available at the Australian National University and Origin Energy