The Sidel Systems company began in 1978 and since then they have incorporated flue gas condensers into their projects. For the Sidel Systems company and their customers, throwing away energy was not an option; even as cheap as natural gas was in those days. To most industry and our governments, natural gas energy efficiency was a non issue. Now because of environmental issues, attitudes are starting to change. Natural gas is North America’s champagne fuel. It is considered the “Clean burning fuel”.

The Sidel Systems company began in 1978 and since then they have incorporated flue gas condensers into their projects. For the Sidel Systems company and their customers, throwing away energy was not an option; even as cheap as natural gas was in those days. To most industry and our governments, natural gas energy efficiency was a non issue. Now because of environmental issues, attitudes are starting to change. Natural gas is North America’s champagne fuel. It is considered the “Clean burning fuel”.

Comparison: Natural gas is delivered to site via a pipeline and not by diesel truck or train. When combusted there is no ash to deal with, or spent rods to store. The emissions from natural gas combustion compared to coal are approximately 1/2. The maintenance between coal or oil combustion compared to natural gas is like comparing night and day. Estimations of global natural gas reserves range between 50 – 100 years, so there no immediate concern about running out of this fuel source. But there are still greenhouse gas emissions associated with the combustion of natural gas. As with every combustion appliance there is a chimney. What goes up these chimneys is the waste heat that did not make it into the process. It is considered by industry as “the cost of doing business”.

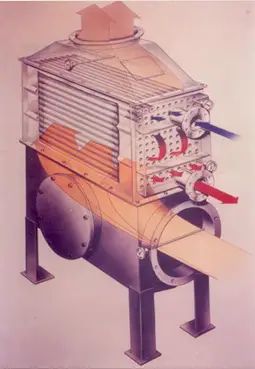

What it really is though, is a lot of wasted energy! Natural gas is a fuel source that can be combusted to over 90% energy efficiency. Instead of emitting hot exhaust gases, and using flue gas condensers, the heat can be recovered from these waste exhaust gases, and cool exhaust gases will then be vented into the atmosphere.

This recovered energy then has to be utilized, and there are many ways for this to be done.

This recovered energy then has to be utilized, and there are many ways for this to be done.

If an industrial complex that requires heated water were to be located near to this power plant, it could be making use of this heated water, and by doing so it would be reducing its natural gas consumption by not having to produce this heated water itself. This recovered energy could be put into a district heating and cooling network, providing low cost heating and cooling to the community.

A large scale greenhouse facility could be constructed, and this recovered energy could be used to heat and cool and even provide irrigation water to this facility. The local community could find employment growing fruits and vegetables and flowers, providing a further benefit to the local community.

Industry can be using flue gas condensers to recover the waste heat from their natural gas appliances and putting this heat into their process or plant wash down requirements. Hospitals, schools, universities, prisons and hotels can be using this recovered energy for space heating and heating their domestic water, or even to heat the swimming pools. There is no reason keep wasting energy.

The DOE states that for every million BTU’s recovered from these waste exhaust gases and then utilized, 118 lbs of CO2 will NOT be vented into the atmosphere.

Not only would the emissions of a coal fired power plant be reduced by 1/2 by converting to natural gas, but it would again be reduced by applying the technology of “Condensing Flue Gas Heat Recovery”. These power plants instead of operating at 35% efficiency, could be operating at well over 80% or possibly even 90% efficiency.

Coal fired power plants in the USA are the largest stationary emitter of CO2 emissions. It is time to show the world that the United States of America is going to set the example and do its part to reduce greenhouse gas emissions by converting these coal fired power plants to natural gas, and then by having these power plants use this natural gas efficiently by hosting this waste energy for further use.

This Flue Gas Condensers technology is not only designed for power plants, but for all government and commercial and industrial buildings and facilities that consume natural gas to provide building space heating or heating of process or domestic water, or even to heat swimming pools.

If this technology is applied to its greatest energy saving potential all that is left after complete combustion is cool exhaust and water. This created water must also be utilized, conserving ground water. This is how efficient natural gas can be used.